LPG Automation Systems

Record and control all LPG movements from the filling facility to the fuel station, from fuel station movements to customer transactions. Check information instantly and provide central monitoring for distributor companies.

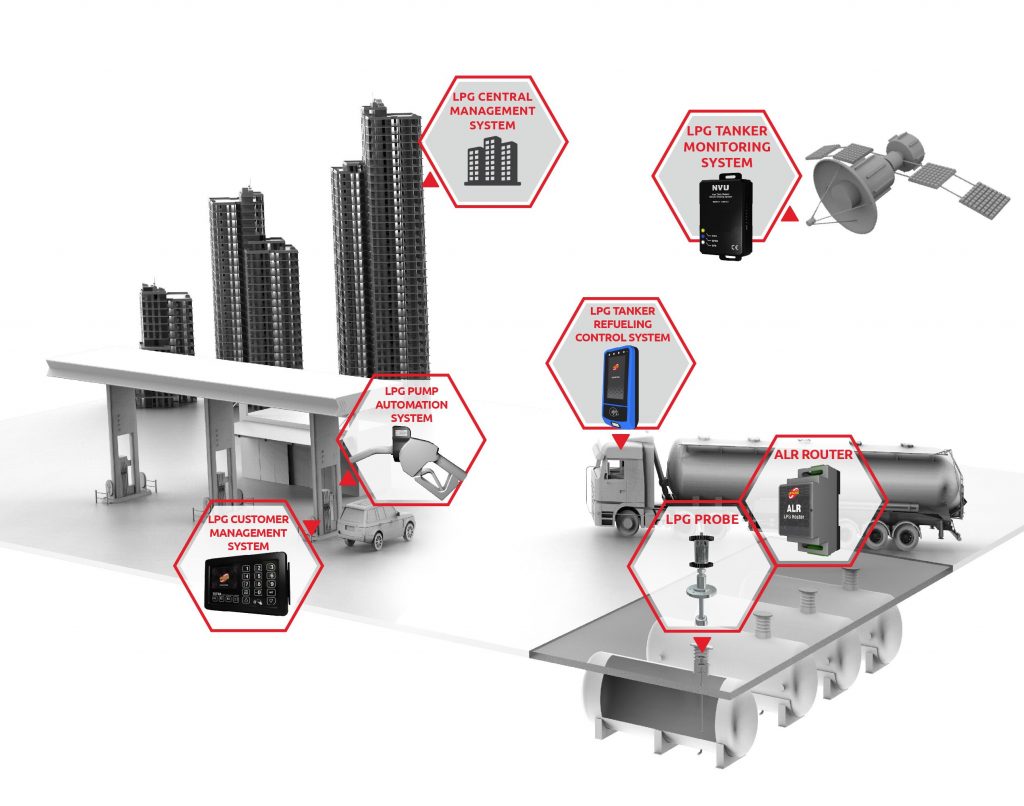

LPG.Net LPG Automation Systems

Petech LPG automation systems can record and control all LPG movements from the filling facility to the fuel station, from fuel station movements to customer transactions. With the system that offers special solutions to all LPG processes, LPG refueling of tankers, LPG level in tanks, etc. information can be checked instantly. It also provides central monitoring for distributor companies.

System Basics

Stations can give their LPG orders through the system. The order received at the center is processed after the loan query in the distributor´s financial system. The system alerts the stations with unsuitable credit. Dealers can also view the status of their current orders and the information of their past orders through the system.

Approved orders are electronically transmitted as refueling orders to the tankers defined in the system and assigned to the distributor regions. More than one work order can be assigned to a tanker. While the distributor users assign tasks to the tankers, they select the fuel on the tanker, the orders they have, and the location on the map by seeing them on the systems.

When tankers arrive at the station for refueling, they receive the confirmation that they are at the correct station electronically from the center by location control over the automation system on the tankers. Tanker automation system allows it to fill only up to the approved order quantity and stops the refueling when it reaches the approved value. The refueling information will be recorded and sent to the central system automatically. It is also transmitted electronically from the center to the financial system and invoices can be issued.

If the LPG probe or ALR’s developed by Asis are at the stations, the LPG tank data is also sent to the central system. Thus, LPG central monitoring will manage and keep track of LPG tank levels in the stations, creates distribution orders on behalf of station manager, matches fillings made at the stations with the orders and compares whether filling is made from a different point.

The amount of refueling made from the storage facility to the tanker is entered into the tanker´s automation system. The system deducts the supplies it makes to the stations from the tanker inventory and continuously sends the printed inventory data to the center. Thus, refueling orders can be managed more effectively.

Because of the integration with distributor’s ERP systems, e-waybill documents of tanker supplies are transmitted to the LPG management system and from there to the tankers and displayed in road inspections.

The automation system on the tanker can, if desired, print receipts after supply to the station. Refill receipts are printed on papers designed according to the distribution firm´s standards and institution.