Vehicle Identification Systems

Control the refueling of fleet customers with our advanced vehicle recognition UHF technology. Maximize system security with electronic and mechanical tamper protection both in vehicle tag units and gun antennas.

Cyber TTS® Vehicle Identification Systems

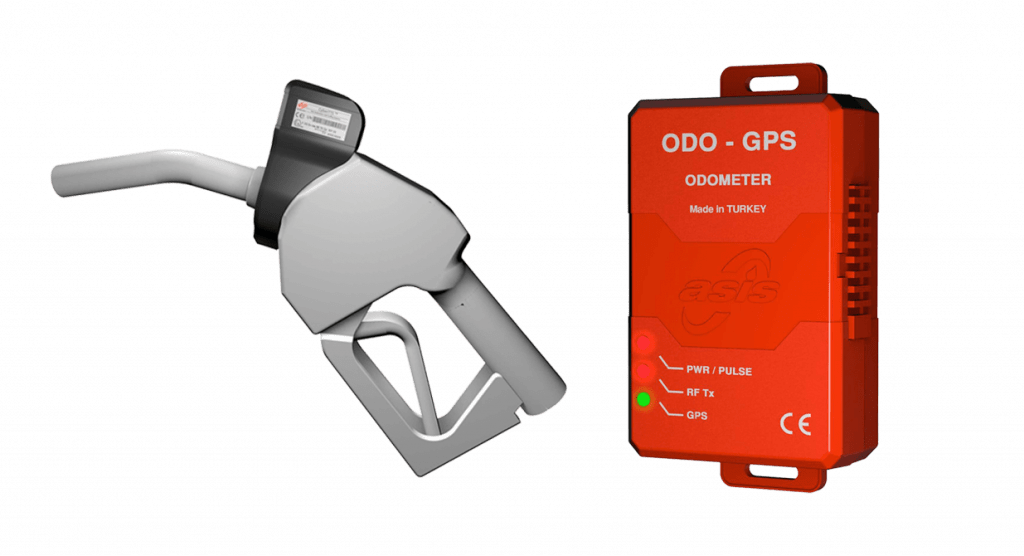

This is a customer management system that controls the refueling of fleet customers, where special limit and constraint programs can be implemented and operates as a module under Asis pump automation. It is a customer recognition system on the basis of vehicle recognition system, and it is differentiated into customer recognition systems especially with the advantages it provides to fleets. Working principle; It is in the form of reading a tag attached around the vehicle warehouse with a special tag reader unit installed on the gun that fills the vehicle, and replenishment after the system approval processes. With this method, the system is guaranteed to supply the specified vehicle. Cyber TTS vehicle recognition systems developed by Asis offer its customers the most advanced vehicle recognition technology with its advanced technology and advanced security options. Besides reading the tag with UHF technology, there is electronic and mechanical tamper protection both in vehicle tag units and gun antennas. In addition, thanks to the technology of controlling the 3D gun movements in the gun reader unit, system security has been maximized by preventing the supply to the vehicle in unwanted gun supply positions. The end-to-end ATEX approval of the system has enabled it to fully meet the safety standards. In addition to vehicle identification detection, if Odometer devices are also included in the system to obtain vehicle km data, the mileage values of the vehicles and / or engine hours of operation can be transferred to the automation system during each replenishment, thus, the consumption calculations of the vehicles can be made. Capable of integrating with Asis NeoFleet map platform.

System Basics

The vehicle identification readers installed on nozzles are completely designed with wireless architecture. The life of the batteries of these readers as active units is minimum 2 years for a gas station with medium level of traffic intensity. The batteries of the readers can be replaced on the site.

There are chips with some vehicle information on the antennas installed on the vehicles. Vehicle antennas, which are protected against external interference, lose their functionality if disassembled or deformed after assembly. In this way, high level of security is provided.

This unit is installed inside the vehicle and transmits the odometer values to the automation system.

Once the nozzle is ed in the fuel tank of a vehicle, the reader on the nozzle safely reads the vehicle’s ID information from the antenna chip of the vehicle, as well as the data from the Odometer Pulse or Odometer GPS as the case may be and transmits them to the automation system. The automation system transmits these data to the Asis Central Management System to obtain approval from the center for fuel supply. Once the approval has been obtained, the automation system instructs the pump to begin supplying fuel. Following completion of the fuel supply, the automation system records the fuel supply details as well as other data obtained from the vehicle and transmits them to the center simultaneously.

A high-level contactless reading technology is utilized between the vehicle antenna and the nozzle reader. Furthermore, the reading intensity of the system can be adjusted parametrically to eliminate any reading problems on vehicles with different types of fuel tanks. The system also prevents supply of fuel to other vehicles while supplying fuel to a specific vehicle by removing the nozzle.

All vehicle identification system components are ATEX certified and they are suitable for use at gas stations and on vehicle fuel tanks. The contactless communication between the vehicle unit and the nozzle is protected by means of a special encryption method to provide complete security.