Tank Automation Systems

Manage all functions inside the storage tanks such as tank inventory, tank fillings and tank alarms. Tank automation software ensures the safety of the system and examines, manages, records and reports the fuel, water and temperature movements in the tanks.

Petech® Tank Automation Systems

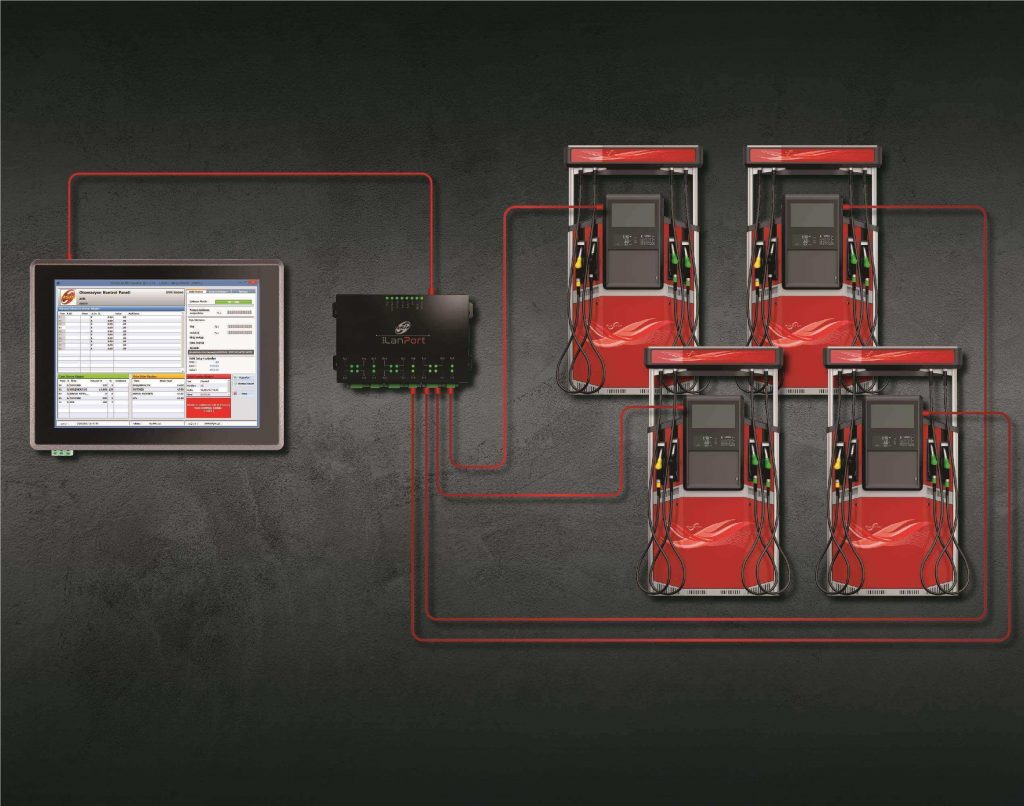

The system that manages all functions inside the storage tanks. Measuring the current tank inventory, tank fillings, and tank alarms, it controls the in-tank movements. Ideal for gas stations with suitable infrastructure for cabling.

Tank automation software communicates at high frequency through the barrier unit ProbeX, which ensures the safety of the system, examines, manages, records and reports the fuel, water and temperature movements in the tanks in high resolution. Thanks to the recording of all movements in the system, historical data can be easily accessed. Fuel storage and monitoring activities, which are very important in terms of safety, environmental factors and commercial aspects for a station, are completely under control thanks to the tank automation system.

System Basics

Volume and height data of the fuel and water inside the tanks, the capacity of the tank, empty volume of the tank, as well as the temperature of the fuel inside the tank can be displayed on the screen and reports can be generated.

Detects tank fillings automatically, displays the tank inventory data before and after each filling. Owing to integration with the pump automation system, generates accurate filling reports by also including the sales transactions made during filling operations.

It is possible to enter the amount to be filled, as well as the waybill/invoice number, prior to the filling operation; and following completion of the filling operation, by clicking on the completion button, the formal document data are also recorded in addition to the filling values.

The system automatically detects and records any unwanted situations such as excessive filling, high water level, low fuel level, high temperature, etc. and displays them as additional information on the inventory screen.

Inventory values of tanks, alarm data, statistical reporting of fillings.

Tank inventories are recorded and reported at predefined times. Thus, it provides information about the past of the in-tank movements.

The system operates in integration with the pump automation. In systems equipped with tank automation, it matches the pump sales with tank inventories for automatic calibration of the tanks.

The system works integrated with pump automation. In systems with pump automation, it allows the system to calibrate tanks automatically by matching pump sales with tank inventories.

Allows creation of a variety of filterable reports for sales transactions, pumps, pump attendants, products, etc. and they can be converted into a number of file formats.

The system is fully compatible with the Asis Central Management System (Petech Online). All sales from pumps are transmitted to the center online. Sales models requiring central authorization are utilized and all daily opening and closing data are collected and transmitted to the center at the midnight.

Apart from Asis probes, many different brands of probe and tank are integrated with the automation console. Currently integrated tanks and probes; Asis, VeederRoot, Fafnir, OPW, Start Italiana, MTS, Hectronic, MLB. Thanks to its integration capability, current investments of distribution companies and / or stations are protected, and a standard management system independent of hardware is created.

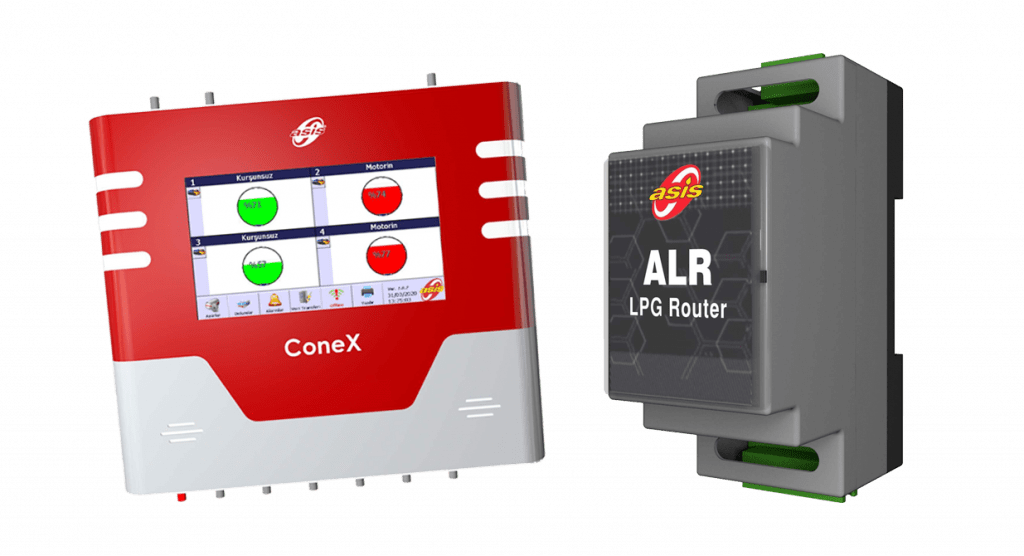

It is fully compatible with TRU, ALR equipment, providing additional control mechanisms for tank automation functions.

Automation software at the stations can be updated automatically by the Central Management System. The need for continuous improvement of both station automation systems and central systems according to customer and market demands is emerging. The fact that the stations can be located in different locations and / or the number of centrally managed stations both extends the operation of the systems on site and increases the service costs. Thanks to the ability of Asis automation systems to be updated automatically remotely, these operations can be carried out both costlessly and very quickly.

System Components