Mobile Container Automation Systems

A mobile station and automation system consisting of tank, pump, mechanical devices and automation system, placed inside standard-sized containers. Designed particularly for supplying fuel using mobile systems and automation management.

Mobile Container Automation Systems

A mobile station and automation system consisting of tank, pump, mechanical devices and automation system, placed inside standard-sized containers. It is designed particularly for supplying fuel using mobile systems, and automation management.

System Basics

The system enables creation of a storage capacity between 10.000 and 30.000 liters in a standard 20’ or 40’ container. The tanks are manufactured to the internationally recognized standards, and can be designed as per customer specifications.

Suction pumps are generally utilized in container systems. As standard, our systems use standard flow rate and single nozzle, but, the number of nozzles and supply flow rate can be customized to customer requirements.

Steel mechanical installations in sizes and quality used at standard gas stations. The equipment used on the installations can be arranged specially depending on customer requirements.

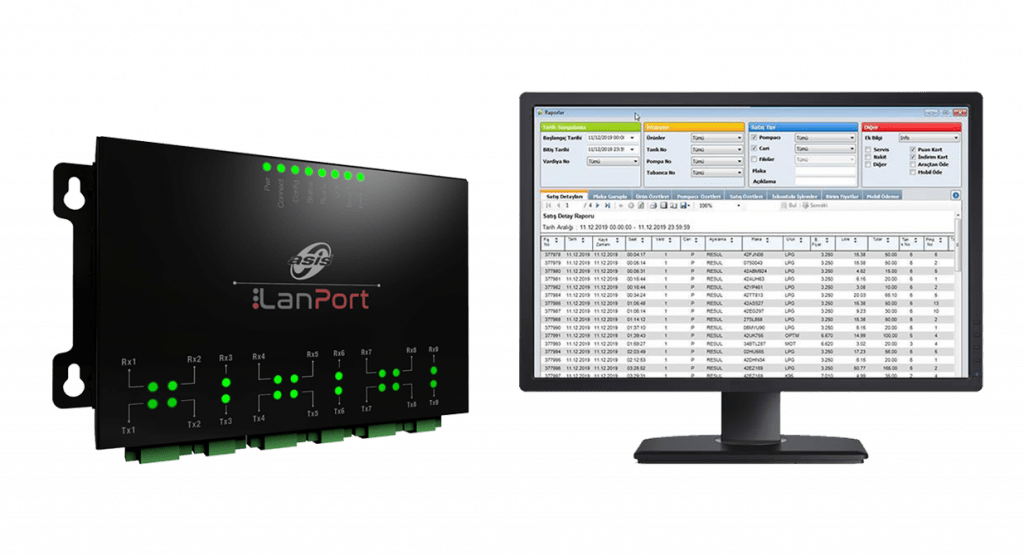

An automation system architecture exactly the same as that of gas stations is used. It is possible to add other automation modules depending on the customer requirements and needs. The only difference from the gas stations is use of industrial models particularly in PC-based hardware.

Alarm systems, gas detectors, fire extinguishing systems, etc. can be included in the system as per the customer requirements.

Automation software at the stations can be updated automatically by the Central Management System. The need for continuous improvement of both station automation systems and central systems according to customer and market demands is emerging. The fact that the stations can be located in different locations and / or the number of centrally managed stations extends the operation of the systems on-site, both in terms of time and increases the service costs. Thanks to the ability of Asis automation systems to be updated automatically remotely, these operations can be carried out both costlessly and very quickly.

System Components