Fuel Storage Facility Automation

Monitor which fuel station, which tanker, which driver, by which attendee, to which compartment of the tanker, how many liters of which product is supplied from a single point, and simultaneously monitor the fuel inventories of the facilities in the system.

Petech® Fuel Storage Facility Automation

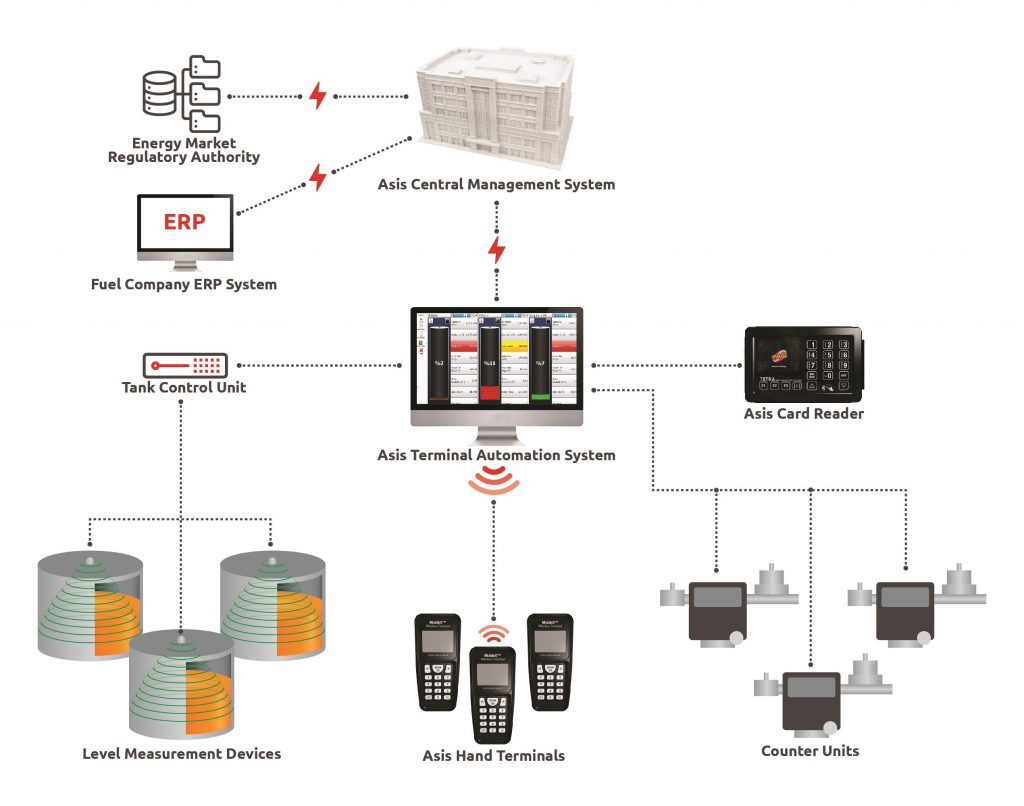

It is an automation system solution that monitors which fuel station, which tanker, which driver, by which attendee, to which compartment of the tanker, how many liters of which product is supplied from a single point. Thanks to many smart control mechanisms such as refueling without financial approval with the dealer order system, and prevention of supply in case of tankers and/or driver document problems, it has been ensured that the distributor or stations are fully compliant with the official and safety rules. In addition to the management of supplies, it is possible to simultaneously monitor the fuel inventories of the facilities in the system. The system, which provides information about the stock deviation by controlling the incoming and outgoing fuels in the facilities, has also increase the stock control processes of the facilities.

System Basics

All tankers that will supply from the facility must be defined in the system. The information of the tanker such as the special license, license information, permits belongs to the tankers are also completely defined in the system within the tanker definitions. Before the supply, the validity of information of the tanker is checked according to the parameters defined in the system. This way, the tanker is prevented from having penalties during its journey, and warnings are generated to remedy its deficiencies. Since tanker information is recorded within refueling data, and which refueling is done with which tanker is known in the system.

Prior to supply, the validity of the tanker information is checked according to the parameters defined in the system. The system does not query the previously registered information. The validity periods and contents of the driver´s documents are also checked by the system, and the system prevents replenishment in contradictory cases. Driver data associated with tanker data are also transferred to supply records.

A supply with order confirmation is distributed to the compartments of the relevant tanker. The amount of different types of filled products to each compartment of the tanker is entered by the operators. The filling amounts are also controlled by the system according to the transport capacities of the tankers, and out-of-capacity filling entry is not allowed. Thus, the filling order of the tanker is created.

The automation system ensures that the tanker arriving at the filling point is filled according to the relevant order. The filling operator at the facility reads the tanker card through the MobileX hand terminal developed by Asis, sees the tanker order data on its screen and chooses from which filling arm to which compartment of the tanker will be refueled. According to the selected filling arm information, the automation system ensures that the filling arm is supplied with the corresponding order value.

After the facility operator use tanker card, the system asks him to have his card read as well. Thus, which supply is made by which operator is also recorded in the system.

After the completion of the fillings, the supply data is automatically sent to the ERP system at the facility or distributor center, and e-invoice and e-dispatch note are generated.