Pump Automation Systems

Maximize station efficiency by saving time on basic operating processes such as calculating pump sales on volumetric and amount basis, grouping by pump officers, shift operations, and eliminating the risks of potential miscalculations or reporting.

Petech® Pump Automation Systems

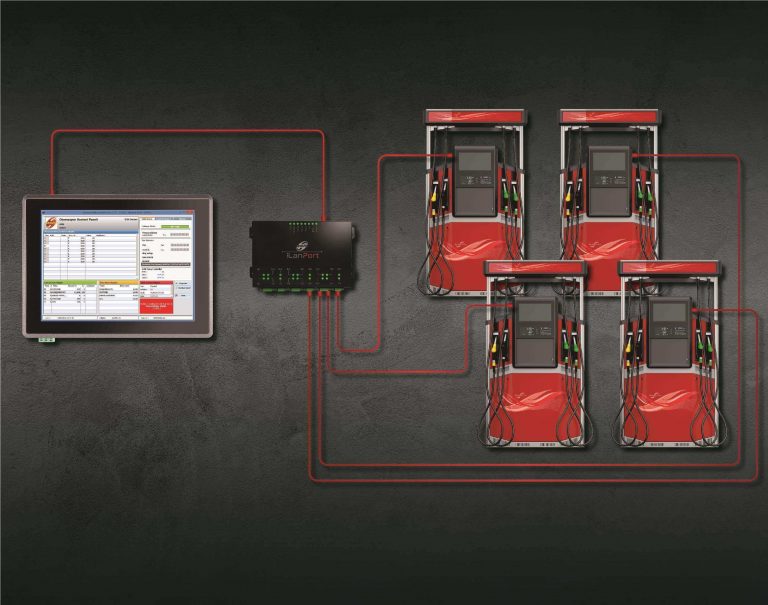

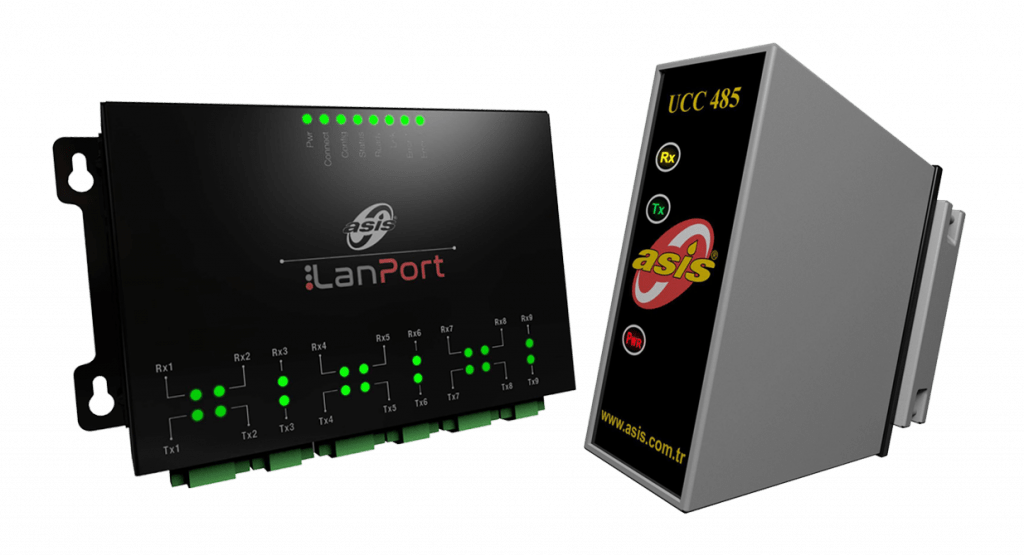

The system that manages the pumps in the gas station automation system. Allows full control over pump sales, unit price management, shift application, and pump attendant and customer management. It provides compatibility for all kinds of station infrastructures thanks to wired and wireless applications. Pump automation system maximizes station efficiency. It saves time in basic operating processes such as calculating all pump sales on a volumetric and amount basis, grouping by pump officers, shift operations, and completely eliminating the risks of potential miscalculations or reporting. Thanks to the system, shift operations, which take 20-30 minutes on average, decrease at the level of seconds. Thanks to the recording of all movements in the system, historical data can be easily accessed. In summary, Asis Pump Automation Systems that control all front field movements in a station are indispensable solutions for distribution companies and station managers.

System Basics

Amount of the fuel supplied is indicated in liters and monetary value simultaneously on the customer screen at the supermarket during a sales transaction.

Integration is possible with many known pumps. Pumps and metering equipments with the system integrated; Petposan, Europump, S4, Mexan, Gilbarco, Tokheim, Mepsan, Baransay, Wayne, Yenen Gaz, Ruby, CSA, MITES, Bennet, VEGA II, IPT-ECR79 Tanker counter, Scheidt & Bachmann, Midco, Prowalco, Elettrogas CNG, Compaq CNG, As if. In addition, the cash registers with the system are integrated Profilo, Mepsan, Beko, Turpak. If the communication protocol and simulator for the pumps that cannot be integrated can be provided, such pump systems can also be integrated within one week.

Totalized data on each pump and dispenser are transferred to the system after each sales transaction. Any differences between the sold amount and the totalizator value are identified and reported by the system.

Unit prices can be changed right on the system, without a requirement to change the unit price on each dispenser. New unit prices entered are automatically registered on each pump and unit price changes can be reported on user basis.

Using a card or vehicle ID unit predefined on the system or after advance payment at the supermarket, the respective pump is turned on by the automation system, allowing customers to fill their fuel tanks themselves.

Once the shift program and shift changes are defined in the system, shift changes can be achieved by pushing a single button. All sales transactions, pump attendant details and fuel type data are transferred to a special shift account for reporting.

It operates in integration with the tank automation system. In systems equipped with tank automation, it matches the pump sales with tank inventories for automatic of the tanks.

In case of connection of a UPS conforming to the system, it reports the status of the UPS; and in case of a UPS problem or problem with batteries, the smart system is shut down in safe mode automatically.

Any unwanted situation in the pump automation software, peripheral hardware and in the operation of the system are detected and alarms are generated accordingly.

Limitations, discounts, etc. can be applied to any pre-defined current accounts and all current sales transactions are managed and reported by the system in a different status.

Misfueling Prevention System which can be optionally added to the automation system, ensures that the refueling to the vehicles coming to the fuel stations is safe and accurate. The system prevents supply mistakes thanks to its large database. Misfueling Fuel Prevention System; compares the license plate of the vehicle in the database with the plates of the vehicle that comes to the pump before refeuling. If the vehicle defined in the system, the automation system checks whether the correct refueling has been made. If it is the right product, refueling starts; if it is not the right product, the system warns and does not start the refueling. If the vehicle that will be refueled is a new vehicle, the type of fuel can be defined with simple security steps in the system. This way, the possibility of wrong refueling is eliminated.

Allows creation of a variety of filterable reports for sales transactions, pumps, pump attendants, products, etc. and they can be converted into a number of file formats.

All pump sales are sent to the center online, sales models that require central authorization are applied, daily opening and closing data are compiled by the system and sent to the center at midnight.

Automation software at the stations can be updated automatically by the Central Management System. The need for continuous improvement of both station automation systems and central systems according to customer and market demands is emerging. The fact that the stations can be located in different locations and / or the number of centrally managed stations both extends the operation of the systems on site and increases the service costs. Thanks to the ability of Asis automation systems to be updated automatically remotely, these operations can be carried out both costlessly and very quickly.